November 14, 2025 Gerdau Ameristeel Tour

Gerdau Ameristeel hosted SAE Manitoba at Gerdau's Manitoba Rolling Mill in Selkirk. The Manitoba rolling mill started from humble beginnings making horseshoes at the beginning of the 1900's and grew to rolling commodity shapes for industrial needs over time. Gerdau purchased the mill in 1995 and has been operating it since.

The rolling mill employs an electric arc furnace that is fed 100% recycled steel scrap for melting. This scrap comes from a variety of sources; from soup cans to cars. The furnace can melt up to 60 tons of scrap at a time. Gerdau's electric arc furnace is one of the greenest furnaces in the world, owing to the use of 100% recycled steel feedstock and Manitoba Hydro's low-carbon-footprint hydroelectric power. While the Manitoba rolling mill is one of Gerdau's smallest facilities, the Selkirk mill produces the widest variety of shapes of all of Gerdau's mills. This variety, combined with the low-carbon-footprint helps the Manitoba location punch above its weight within the Gerdau organization and the global market for hot-rolled shapes. The facility tour started with the furnace building for melting steel. The group was fortunate enough to witness the end of a melt cycle with the tapping off (pouring) of the molten steel from the furnace to the ladle. The molten steel in the ladle would later be transferred to the continuous casting line to be cast into steel blooms that would later be processed in the rolling mill. The rolling mill was a highlight of the tour as it showcased the high level of automation present. Very few people were present as the red-hot steel bloom passed through the various rolling stands as the steel shape was being formed. At the end of the rolling line where the hot rolled shapes are held after completing the rolling process was a new addition; an articulated robot that automatically cuts QA samples from the end of the bar and transfers them to a secondary station for further processing. The use of a robot in this extremely challenging environment has taken nearly a year to commission into service. This robot eliminates the previously manual process where workers would cut samples by hand with torches and transfer the red-hot samples with handheld tongs. The use of a robot dramatically improves the safety of workers as well as improving consistency of the samples. Other areas toured included cutting/bundling area where the rolled products are cut to lengths appropriate for transport and bundled for shipping; as well as the QA labs where mechanical and chemical properties of the cast blooms and rolled products were inspected against internal and customer requirements. About the company: Gerdau was founded in Brazil in 1901 and is one of the largest steel manufacturers in the world. It produces around 11.5 million metric tons of steel product annually and employs over 30 000 people across 7 countries within North and South America, including Canada. Gerdau’s steel products can be found in various applications, from the elevator shafts of metropolitan skyscrapers, rail systems covering vast distances across continents, cutting edges of earthmoving equipment, and trailer decks of over-the-road trucking. Acknowledgements: SAE Manitoba would like to thank Gerdau Manitoba Rolling Mill for hosting our members, as well as sponsoring lunch for the attendees. Specifically SAE Manitoba would like to thank Derek Schmidtke (engineering), Stephen Duynisveld (engineering), Nick Klassen (melt shop), Grace Capar (rolling mill), Kyle Marykuca (rolling mill), and Shenille Tetrault (safety manager) for being our tour guides, presenters, and subject matter experts. Their time and generosity is greatly appreciated.

October 29, 2025 Engineering Design 101 for UMSAE Teams SAE Manitoba, in conjunction with UMSAE, hosted a special technical seminar titled: "Engineering Design 101 for UMSAE Teams" at the University of Manitoba. This event was primarily aimed at new UMSAE members to help them understand & manage the unique intricacies of SAE competition projects. Topics covered included defining requirements, the development process, documentation, design verification, and competition logistics. Punctuating the presentations were excerpts of hard won victories and first-hand experience from Ed's time with UMSAE as a participant and as a faculty advisor.

About the presenter: Ed Hohenberg is a professional engineer with expertise in automotive engineering, auto racing, and engineering education. Ed has worked in the automotive industry as an Engine Test Engineer, Powertrain Development Engineer, Vehicle Dynamics Engineering Zone Leader, and as a Project Engineer in Advanced Product Planning, developing new and advanced vehicle technologies. While in industry, Ed was awarded patents and other industry awards for his engineering work. In 2001, Ed left industry to join the faculty of Mechanical Engineering Technology at Red River College, where he served as an instructor, worked on automotive engineering applied research projects, and advised students on the Solar Race Car Team. Alongside his industry career and teaching career at Red River College, Ed had been a sessional lecturer for the Internal Combustion Engines and Automotive Engineering Design courses at the University of Manitoba starting in 1994, and a technical advisor to the UMSAE Formula team. In 2012, he was hired as the full time Faculty Advisor to the U of M SAE student organization, which quickly grew to 5 teams with over 300 student members, and became the largest student SAE chapter worldwide. In 2019, Ed won the prestigious SAE/SCCA Carroll Smith Mentor’s Cup for his efforts as Faculty Advisor. For over 20 years, Ed has also volunteered on the governing board of the SAE Manitoba Professional Section and is currently the Vice Chair. In his spare time, Ed has been successful in several forms of motorsports, contributed technical articles to several automotive magazines, and runs his own race engine calibration business. Ed is an engineering graduate of the U of M, with both B.Sc. and M.Sc. Degrees. As an undergrad, Ed was a founding member of UMSAE, and established the UMSAE Formula Team. From Red River College, Ed also has a Certificate in Adult Education. Acknowledgements: SAE Manitoba would like to thank our presenter Ed Hohenberg for his time and sharing his knowledge, UMSAE for organizing the venue, as well as all of the attendees.

October 23, 2025 Navigating the Engineering Design Process: Understanding the Assignment

SAE Manitoba, in conjunction with UMSAE, hosted a special technical seminar titled: "Navigating the Engineering Design Process: Understanding the Assignment", at the University of Manitoba. This event was intended to provide UMSAE members with tools to help understand & manage the more non-technical aspects of design work.

SAE Manitoba would like to thank our presenter David Chuang for his time and sharing his knowledge, UMSAE for organizing the venue,; as well as all of the attendees.

.

January 22, 2025 Student Night

SAE Manitoba hosted Student Night at the University of Manitoba. This event was centred on UMSAE students and celebrates their participation in SAE. The Student Night event is intended to be a networking opportunity with professional SAE MB members, and to highlight member contributions to local industry.

The evening began with a presentation by Corey Dyck on the topic of "Performance Driving Techniques". This presentation introduced the basics of the "driving line", tire/road interaction, and mental aspects to driving fast in motorsports.

After Corey's presentation, the evening's participants were then presented with an automotive engineering design challenge: to construct a balloon powered car designed to travel the furthest possible distance using only the supplied materials and in a fixed amount of time.

Teams were created from the participants, with one professional member and several student members per team for a total of seven teams. The teams were presented with the rules and restrictions of their design, and given a short period of time to examine the materials and formulate a design. Once the design time had expired, the teams were called up one at a time to select their materials of choice. To discourage hoarding of materials, all unused materials would have to become ballast.

Worst Result:

About the presenter:

Corey is a University of Manitoba mechanical engineering graduate working in the heavy transit industry here in Winnipeg. For 19 years he has followed his passion of racing, competing in autocross style racing. With a few Canadian National Championship wins, and placing top 10 in the US National championships several times, he has plenty of experience which he applies to a driving school in Winnipeg.

SAE Manitoba would like to thank our presenter Corey; as well as all of the students that attended in order to make this night possible.

On October 25, 2023 David Chuang hosted a tour of NRC’s lab in Winnipeg for SAE Manitoba. To begin David gave a presentation showing some of the history of NRC as well as their goals to advance manufacturing in industry and give opportunity for continued research for those in academia.

David Chuang graduated from the University of Manitoba in 2003 with a Mechanical Engineering degree. While in University, David was involved with UMSAE design teams in Aero Design, Mini Baja, and Formula SAE; as well as holding Treasurer and Chair positions at various times. Since graduation, David has been involved in various segments of mobility and manufacturing industries for over 20 years. His past positions have covered design & testing of power sports vehicles, heavy vehicle chassis, agricultural machinery, and mobile electronics. David joined NRC in 2011 as a Test & Evaluation Engineer based in Ottawa; focusing on the testing of heavy truck, bus, and light vehicle platforms in support of NRC's mobility mandate. In 2020, David transferred to Winnipeg to support the starting up of NRC’s new Advanced Manufacturing Research Facility as a mechatronics engineer.

After his presentation on the history of the NRC and their future goals, David gave a tour of the facility including their 3D metal printing machines (shown above) where we could talk to the operator and watch a part in the process of being printed. We were also able to handle some sample parts that had been printed earlier, some of which had not yet been cut from their base plate. Later we were able to see the wire EDM (Electrical Discharge Machining) used to cut parts from their base plate following printing. Additionally in a separate room, we were shown the coordinate measuring machine (shown at right) used for taking accurate measurements of many types of parts, in this case to measure the warping of their 3D printed metal parts before and after sintering.

In the main open shop there was an area marked off for planning a future plastic film production line, and beyond that was a very large 3D printer comprised of an ABB robotic arm and servo equipped with a large extrusion nozzle for 3D printing thermoplastics with a printing bed attached to a servo. By using the degrees of freedom of the arm and printing bed

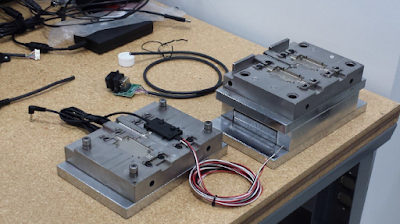

together, complex shapes can be more easily printed by taking advantage of changing the direction of the part being printed in relation to gravity. With the range of movement allowed by the robotic arm, more complex shapes can be made than a standard 3 degree of freedom 3D printer that is more familiar to most of us. Additionally the extruder can print using filament, or taking advantage of standard plastic pellets used in injection molding which allows for a wide variety of materials to be used. In the corner behind this large 3D printer is an injection molding cycle testing setup for testing 3D printed metal molds. This is one good example of how the NRC lab in

Numerous lab spaces were shown along the hallway, two were used to test sustainable packaging under both aerobic and anaerobic condition, while checking the decomposition of the sample materials. In another room other machines tested fatigue and creep at elevated temperatures. We were also able to visit the machine shop where they have an assortment of tools and machines to assist them in building and maintaining the apparatuses they use.

Exploring the NRC facility in Winnipeg was an eye opening experience, showcasing their current abilities, rich history, and future goals. Each portion of the lab complemented another area and we were able to see how a project could be carried out from initial concept to final testing. Seeing the sustainable packaging decomposition testing showed their commitment to sustainability, while many rooms reserved for upcoming industry projects showed their commitment for continuous improvement and innovation.

SAE Manitoba would like to thank David Chuang for his engaging and informative tour through NRC’s facility. His expertise and enthusiasm for the work he does made it a memorable and enjoyably experience.

The Royal Canadian Mint

Polaris

October 24, 2019

The World’s Fastest Indian Motorcycle

October 11, 2018

| Richard standing at the inlet of the wind tunnel (credit Ryan Thomson) |

Manitoba Public Insurance J.W. Zacharias Physical Damage Research Centre

February 6, 2018

| Cameron Huber (left) with SAE’s Ed Hohenberg - Credit Ryan Thomson |

| MPI’s tire changing machine is one of the only in the province capable of servicing carbon fibre wheels - Credit Cameron Huber |

| MPI is performing a time study to determine whether it is more cost effective to repair or replace a panel - Credit Cameron Huber |

| Brett Bergen explains an issue with a Civic’s wastegate location, and the RCAR petition to make it a serviceable component - Credit Cameron Huber |

We would like to thank Cameron and Brett for the engaging presentation and exciting tour.

Racing Cars and the Importance of the Human Machine Interface

November 9, 2017

| Cory explaining traction (Credit: Ryan Thomson) |

| Podium finishers (Credit: Megan Robinson)

We would like to thank Cory for his engaging presentation and are looking forward to featuring him in an SAE Manitoba event again soon.

|

Tour of Industrial Technology Centre

September 21, 2016

Magellan Aerospace – Winnipeg Advanced Satellite Integration Facility

May 18, 2016

February 24, 2016

John began working for Boeing in 1996 as an engineering summer student. Over the years he has worked in various design and manufacturing roles, and is currently working in tooling engineering supporting the 737 MAX program. John has been a member of SAE since 1997, and was the SAE Formula team lead in his graduation year, 1998.

|

| Credit: Ed Hohenberg |

|

| Credit: Ed Hohenberg |

Tour of Holley Performance Products Canada

February 4, 2016

|

| An injection mold for a small electronic component housing. Credit: Ed Hohenberg |

|

| Credit: Irene Wasilewski |

Tour of Fort Garry Fire Trucks

November 10, 2015

Written by Ryan Thomson

On Tuesday, November 10th, Mr. Gordon Draskovic P.Eng. gave a presentation of Fort Gary Fire Trucks (FGFT) and a guided tour of the company design and manufacturing facility. Mr. Draskovic has been with FGFT for 12 years and has spent his working career focusing on diesel engines and vehicle systems design and integration.

Tour of MacDon Industries Ltd.

May 20, 2015

Written by Ryan Thomson

On May 20, 2015, Ben Foster of MacDon Industries Ltd. hosted a presentation focused on the benefits and challenges of Tier 4 emissions standards as they pertain to the company, followed by tour of MacDon’s manufacturing facilities.

The MacDonald family purchased Killbery Industries in 1971. Through the pursuit of harvesting excellence, MacDon continues to be an industry leader in harvesting equipment such as draper, auger, rotary, and pickup headers as well as self-propelled windrowers. Every machine is conceived, designed, and built in Winnipeg, Manitoba, by 1600 employees situated on 900 000 square feet of buildings on over 85 acres of land.

Ben Foster graduated from McGill University as a Mechanical Engineer, and began his career with MacDon in 2011. He started out as a field test technician, working with prototype machines out in the field, reporting the machine’s performance back to the engineers in Winnipeg. He moved into a field test leader role in 2012, now organizing and supervision a crew of field test technicians. In 2014 Ben was offered the position of SP Windrower Product Manager. His responsibilities now include managing and directing the engineers developing the next generation of windrowers.

Ben’s presentation was focused on North American EPA Tier 4 emission standards, and how the standards affect the engineering of the SP windrowers, which use 100-200 HP diesel engines. The emissions regulations vary by geographic location, and different classes of engines often follow different regulation timelines. In order to commercially sell a product with an engine, you must meet these standards or your company will be subject to substantial fines.

In general, diesel engines consume fuel and air, producing work, heat, and exhaust. Diesel exhaust contains, largely; air, water vapour, carbon dioxide, oxides of nitrogen (NOx), Particulate matter (PM), and an array of burnt or partially burnt hydrocarbons, including carbon monoxide. (HC, CO).

NOx emissions are toxic and contribute to smog and acid rain. PM emissions are solid particles of soot, ash, and sulphates that have negative effects on the human respiratory system. HC emissions have an irritating odour, and can be carcinogenic. CO is a colourless, odourless, tasteless gas that is toxic in high enough concentrations.

Tier 4 emissions standards specifically target an 80% reduction in NOx, a 90% reduction in PM, and a 50% reduction in HC emissions from Tier 1 emissions, which were regulated in 1996. There are a variety of strategies and technologies used to reduce these emissions in order to meet the regulations.

Carefully controlling the inputs to the engine; air and fuel, allows for more precise control of combustion and therefore, emissions. Air pre-cleaners, variable geometry turbochargers, and precisely controlled injection are key technologies in improving fuel economy and reducing emissions.

After treatment technologies include Exhaust Gas Recirculation (EGR), Diesel Oxidation Catalysts (DOC), Diesel Particulate Filters (DPF), Selective Catalyst Reduction (SCR), and the use of Diesel Exhaust Fluid (DEF).

EGR routes a portion exhaust gas back through the combustion chamber, processing combustion products a second time. This process adds inert gas to the combustion process and increases heat capacity, which reduces combustion temperatures, which in turn reduces NOx emissions.

DOCs use a honeycomb of precious metals that reacts with and reduces HC and CO emissions at high temperature.

DPFs use a porous medium that captures soot and ash particles from the exhaust. The medium must be cleaned periodically, and is done so through a high temperature regeneration cycle. The regeneration cycle cannot remove all ash and soot from the filter, and must be periodically serviced to remove it manually.

SCR uses ammonia, supplied through DEF, to react with oxides of nitrogen producing gaseous nitrogen and water, reducing NOx emissions. These units must occasionally be regenerated to remove crystalline deposits.

Although most engine manufacturers employ only a selection of these technologies, these after treatments require large canisters in the exhaust system which must be nested under the hood. This presents space, heat, and durability challenges for engineering. MacDon’s M series SP windrowers use Cummins engines, which utilize EGR, DOC, and SCR technologies to meet Tier 4 emissions. The engine bay was carefully organized to maintain a slim hood profile for visibility. The DEF tank was mounted under the platform with the fuel tank, and is heated to prevent the DEF from freezing in colder temperatures. Larger air, water, and hydraulic coolers and fans were used to combat the increased heat rejection requirements. The engineering was done to meet the 2015 release, while staying competitively priced and maintaining or increasing product performance.

Presentation and Tour of Price Research Center North

April 23, 2015

Written by Rohan Lall

May 28, 2014

Written by Irene Wasilewski

New Flyer Industries Electric Bus and the Electric Highway – Presentation and Tour

April 29, 2014

written by Rohan Lall

Presentation and Tour of Parker Hannifin Canada

April 17, 2013

written by Rohan Lall

Ljiljana Zlatanovic-Kovacevic hosted a presentation and tour of Parker Hannifin Canada’s Highly Accelerated Life Testing (HALT) chamber and Parker’s Electronic Controls Division (ECD) production facilities.

The ECD of Parker Hannifin provides recognised original equipment manufacturers with engineering design and production for many electronic devices. They supply components such as sensors, displays, clusters, control modules and Controller Area Network bus controllers to the likes of Bobcat, Case New Holland, Caterpillar and New Flyer. The addition of the HALT chamber will aid in the design of more robust and dependable products, yielding improved reliability in the field while reducing warranty costs. HALT is a series of tests used to find weak links in the design and fabrication processes of a component during the design phase. The tests can be performed in many fashions and are able isolate the limiting factors while sacrificing only a few units. The process is not a pass/fail context but allows for an accelerated testing procedure and provides valuable results within a matter of days as opposed to months or years using other methods.

The presentation and tour were led by Ljiljana Zlatanovic-Kovacevic, a 12-year member of Parker Hannifin Canada’s ECD. As a Design Verification Testing (DVT) Engineering Specialist in the Product Assurance department, her role has been essential in the selection, procurement and maintenance of the HALT chamber equipment at Parker Hannifin. In addition to her proficiency with HALT, Miss Zlatanovic-Kovacevic has a background in Mechanical Engineering and significant experience in other Parker DVT methodologies including vibration, environmental (temperature and humidity), salt corrosion and International Protection sealing codes.

The detailed presentation explained what HALT was, its design and the steps involved in its operation. The benefits of the system and the key differences versus traditional testing were illustrated to the audience. A tour of the facilities followed where those in attendance were shown the HALT chamber and other Parker ECD production areas and equipment.

Thanks again to Parker Hannifin and Ljiljana Zlatanovic-Kovacevic for their time and co-operation.

Winnipeg Transit Presentation, Tour and Ride

November 17, 2012

written by Irene Wasilewski

Winnipeg Transit has a strong history of being an innovator in the industry from 1882 when the first transit ‘vehicle’, which consisted of a horse car, ran to 1971 when the Transit Department of the Metropolitan Corporation of Greater Winnipeg became the first City-owned Transit System to the milestone in 2005 of having half of the fleet consist of easy-access buses (low floor). Winnipeg Transit is continuing the tradition of improving their service through new programs such as real time passenger information, improved stops and the rapid transportation corridor.

The presentation, tour and ride were guided by Winnipeg Transit’s director, Dave Wardrop. Mr. Wardrop has led a team of 1,300 employees through a series of improvements that have successfully expanded transit ridership and service in the City of Winnipeg. Since Mr. Wardrop joined Winnipeg Transit, Transit’s long-standing trend of decreasing ridership has been replaced by 6 consecutive years of growth totaling 19%, or an increase of 7.5 million rides per year.

Mr Wardrop’s presentation highlighted some key changes to transit system. Today’s Winnipeg Transit buses are equipped with GPS, automated stop announcements and on-board cameras among other technology. Winnipeg Transit also boasts a modern control centre at its headquarters that provides real-time service monitoring through schedule exception reporting and voice and data communication with drivers. Winnipeg riders recently began using the new rapid transit corridor that has improved the service connecting many ends of the city.

Mr. Wardrop provided a tour of the main maintenance facility that does a large variety of work to maintain the city’s fleet of vehicles.

The evening ended with a guided ride down the new rapid transit corridor where the audience could get a first-hand look at some of the innovations Mr. Wardrop discussed in his presentation.

For more information on Winnipeg Transit please visit winnipegtransit.com/en

MEVA – Presentation and Display

November 17, 2012

written by Irene Wasilewski

For the uninitiated, MEVA stands for Manitoba Electric Vehicle Association. It is a group of members from a variety of backgrounds that share a common interest in electrical vehicle technology and a desire to promote electrical vehicles as a viable alternative to traditional transportation technologies. The benefits of electric vehicles are discussed at their regular meetings. Some members have electric vehicles they have purchased or converted from standard combustion engine vehicles. Gerry Kopelow of MEVA agreed to provide a presentation regarding vehicle conversion and the need for an alternative source of energy for transportation. The presentation was followed by an opportunity for the public to see their vehicles up close and ask questions of the owners.

Mr. Kopelow has been designing and building mechanical, electrical, and electronic devices for over five decades. He has converted several internal-combustion-engine-driven machines to battery power, including a roto-tiller, a garden tractor, a 5-Series BMW automobile, and a Chevrolet S10 4WD pickup truck. Through an assortment of photos Mr. Kopelow guided the audience through some of his conversions. One of the highlights of the presentation was the step-by-step photo documentation of the Chevrolet truck conversion, from initial drop off at his home, through the ups and downs of the months of rework to future work he intends to do with the vehicle. Mr. Kopelow ended the presentation with a look at the reasons behind moving to alternative energy sources, namely the rapid reduction of traditional fuel obtained from crude oil.

Following the meeting, members of MEVA had brought some of their vehicles, for display and provided the opportunity for the crowd to answer questions of the owners. The vehicles on display included Mr. Kopelow’s Chevrolet truck, the University of Manitoba’s SAE students’ Formula Electric vehicle and Ross Redman’s Mitsubishi i-Miev.

For more information regarding MEVA please visit manitobaev.ca

Presentation and Tour of Intelligent Hospital Systems

March 3, 2011

written by Bob Mai

Intelligent Hospital Systems' Irene Wasilewski was kind enough to host a presentation and tour of the Robotic Intra-Venous Automation (RIVA) system.

The RIVA system is designed to supplement a hospital's IV fluid bag preparation process. The typical procedure, as-is, is labour-intensive, and all the human interaction presents possibility of introducing errors. This could have dire consequences in a hospital setting, given the sensitivity of IV bag formulations. The RIVA system eliminates many potential for errors, as well as being a labour-saving investment, especially for large batch orders. It also reduces the amount of consumables by reviewing its orders and calculating best efficiency.

The RIVA system introduces electronic order entry and integration into a Pharmacy Information System. It is an ISO Class 5 hermetically-sealed environment. It prepares IV bags as well as syringes, with a complete audit trail. As well as excelling in batch orders, it can also operate "just-in-time."

After the presentation, the group was brought to the back of the Intelligent Hospital Systems' facility to watch a live demonstration of an assembled unit in action. After a little bit of debugging, the machine's 7-axis robotic arm and myriad of robotics technologies was impressively producing syringes and bags filled with harmless coloured water.

Thank you to Irene and Intelligent Hospital Systems for this interesting presentation of Winnipeg-based international entrepreneurship!

Presentation and Tour of Carlson Engineered Composites

May 5, 2010

written by Irene Wasilewski

Carlson Engineered Composites Inc’s Rob Haller provided a presentation on the open and closed light resin transfer moulding (LRTM) process, followed by a demonstration of their new seven-axis water-jet robot that will be used for trimming parts after they come off the moulds.

Carlson Engineered Composites Inc. is a manufacturer of fibreglass products for original equipment manufacturers for a wide range of commercial vehicles and equipment. Carlson specializes in assisting the customer at the design stage to ensure high quality, durable products manufactured efficiently. They are a subsidiary company of Carneil Group of Companies which has been serving the industry for over 70 years.

Rob Haller, born and raised in Winnipeg, received his Bachelor of Science in Mechanical Engineering in 1993. He began his career at New Flyer Industries in the manufacturing engineering department and later moved on to become a corrosion engineer and later still to the alternate fuels group. In 2002 Rob moved to Carlson to become their manufacturing engineer and in 2007 was promoted to the engineering manager. Rob was instrumental in developing the company’s LRTM production line.

Rob provided a presentation on the company’s manufacturing processes – open moulding and the newest method, closed LRTM. In open moulding chopped up fibreglass and a liquid resin mix are sprayed onto the surface of a mould. The process is highly dependant on the operator’s ability to control part thickness and glass content. As well, it produces high levels of volatile organic compounds (VOCs) which require facility ventilation and protective gear for the operator. For those reasons, Carlson decided to implement an LRTM line. In LRTM the resin is injected into a channel running the perimeter of a two piece mould. A vacuum is attached to the center of the top half of the mould to control the flow of the resin through the mould. This process has a labour savings associated with it plus improved regularity part-to-part and lower tooling costs. The workshop area is also styrene-free in this process.

The group was provided a tour of Carlson’s production areas starting with the open resin transfer moulding line, then the light resin transfer moulding lineb lastly followed by a demonstration of the new seven-axis water-jet recently installed. The water-jet runs on a track which spans two ‘rooms’. This allows operators to set-up parts in one room while the water-jet is working in the second room. CAD data may be directly imported to the water jet to define the cutting lines.

Presentation and Tour of IMRIS

February 23, 2010

written by Irene Wasilewski

SAE Manitoba hosted an evening at IMRIS on February 9, 2010. IMRIS is a global leader in image guided therapy solutions. IMRIS’s senior technology researcher, Mark Alexiuk, P. Eng, Ph.D. provided a presentation and a tour of the facility. Dr. Alexiuk studied electrical engineering at the University of Manitoba and has been with IMRIS since 2007.

IMRIS currently designs and sells products under three main umbrellas:

1. IMRISNV – Stroke Management and Neurovascular Care

2. IMRISCARDIO – Cardiovascular care

3. IMRISNEURO – Neurosurgery

IMRISNV and IMRISCARDIO are both interventional suites with MR imaging and x-ray angiography. IMRISNV focuses on accurately identifying areas of salvageable brain tissue during a stroke and can assist clinicians in quickly determining specific intervention strategies. IMRISCARDIO focuses on visualizing the heart before, during and after cardiovascular interventions. IMRISNEURO is a one stop shop for an operating and imaging room, combining many technologies into one space such as a movable MR, movable patient tables and data display to name just a few.

IMRIS technologies incorporate a large 1.5T or 3T MR scanner that enters the room on demand. During the imaging, the patient remains stationary on the table throughout the procedure. The tabletop, mattress and arm boards are all MR compatible and radiolucent to optimize image quality. The table can be tilted, rolled laterally and moved horizontally for optimum positioning for imaging and intervention. For MR imaging the table is rotated 90deg and fully extended toward the MR scanner.

Following the presentation there was a tour of the facilities. The first stop was the demo room which houses an MR scanner (with dummy magnets), a patient table and an angiography system to allow the visitor to see how the system fits together and could function in a hospital. Next there was a short stop at the engineering office area followed by the R&D area which housed actual scanners used in developing new product and for testing. The final stop was the manufacturing area.

SAE Manitoba would like to thank Dr. Alexiuk for providing the presentation and tour and IMRIS for allowing us to visit and for providing supper. For more information about IMRIS please visit:

www.imris.com

Manitoba Hydro Place – Tour and Presentation

November 15, 2009

written by Irene Wasilewski

Manitoba Hydro recently opened their new downtown headquarters, Manitoba Hydro Place. This innovative building incorporates many energy saving and healthy workplace features never put together before in a downtown skyscraper. Earlier this year, Manitoba Hydro Place was honoured with a prestigious award from the Council on Tall Buildings and Urban Habitat who named it '2009 Best Tall Building for the Americas.'

The presentation and tour was provided by Tom Akerstream, who is the Manager of Head Office Facilities, Manitoba Hydro, and was the Project Energy Advisor for the Manitoba Hydro Downtown Office Project. Tom has worked in the energy management field for over 30 years. He joined the company 18 years ago to initiate their 'Power Smart' program. He is a past President of the Manitoba Electric League and a member of numerous committees, including Manitoba Hydro’s R&D Board and the CSA Codes and Standards for Energy Efficiency. Tom has a Bachelor of Environmental Studies, a Bachelor of Architecture and a Masters in Architecture.

Even the development of the building design began in an innovative way; it was an integrated design approach from the beginning. Rather than following the standard practice of having the architects design the space, and then pass the design off to the engineers and contractors to build, right from the start, the design process included approximately 30 people from major design areas such as architecture, landscape design, mechanical, etc.

Not only was energy savings a focus but also the comfort of the employees that will use the spaces. Thermal comfort, the effective temperature the employees feel as they work in the space, was one of the key aspects in the design. One of the methods used to achieve this was a displacement ventilation system that circulates the air by adding fresh air at the bottom of the rooms through a raised floor and exhausting air at the top, utilizing the natural flow of air. The ventilation system uses entirely passive systems rather than relying on mechanical equipment. There are 4 to 5 air changes an hour for the office staff.

Also, the lighting was optimized so that everyone has the advantage of natural light. The passive ventilation system adds comfort and is also an energy saver. For example, the underground parkade does not require any energy other than lighting due to the effectiveness of the ventilation system to add heat in the winter and cooling in the summer. The north and south atria are fundamental to the passive system. Fresh air is drawn into the atria where water features humidify the air and waste heat from exhaust air is recovered. Natural solar energy also warms the fresh air. The south winter gardens act as lungs, providing preconditioned fresh air to the building.

The New Flyer Xcelsior XDE40

September 15, 2009

written by Irene Wasilewski

Dean Weiten, SAE Manitoba vice-chair of membership (left), presenting gift to Paul Zanetel, M.A.Sc., P.Eng., guest speakerSAE Manitoba hosted a presentation on September 15, 2009 with featured speaker Mr. Paul Zanetel, M.A.Sc., P.Eng, who introduced the latest New Flyer model, the Xcelsior.

Mr. Zanetel is the current Chief Technical Advisor at New Flyer Industries. He formerly served as the Vice-President of Engineering at New Flyer and has 12 years with the company to date. He is also currently an Engineer-in-Residence at the University of Manitoba.

New Flyer is a publicly-traded company with its roots starting in 1930. They design and manufacture heavy-duty transit service buses and are the market leader in Canada and the US. They are the only transit OEM certified in ISO 9001 (Quality), ISO 14001 (Environment) and OHSAS 18001 (Occupational Health and Safety).

Mr. Zanetel began by providing an update on the activities and accomplishments of the University of Manitoba SAE student chapter (UMSAE), and followed that with some background on New Flyer Industries. The presentation included some of the challenges that the transit bus industry faces in launching a new model. He then provided an overview of New Flyer’s latest model, Xcelsior, describing its advantages over other models. The group was treated to a ride around the surrounding New Flyer facilities on one of the Xcelsior demonstration coaches, with current Vice-President, Engineering Services, Mr. Chris Stoddart serving as the tour guide, where we were able to get a close-up look at the bus and ask questions to many of the designers that worked on the new model.

It was a very informative presentation, even for some of the New Flyer staff in attendance, and was a great way to kick off SAE Manitoba's tech meetings season.

www.newflyer.com

Plug-In Hybrid Update and Manitoba Electric Museum Tour

November 15, 2009

written by Irene Wasilewski

The evening was a mix of technical presentation about the potential power requirements for a relatively new sector in automotive alternative energy, the plug-in hybrid, and a tour of the Manitoba Electric Museum which outlines the history of electric power distribution in Manitoba.

The presentation was provided by Robert Yonza, P.Eng., of Manitoba Hydro. He holds a B.Sc. (Physics) from U of W as well as a B.Sc. (Electrical Engineering) from U of M. Mr. Yonza has worked at Teshmont Consultants and Pauwels Canada before joining Manitoba Hydro as a Grounding Engineer. In 2008 he moved on to the Emerging Energy Systems Group.

Most people have become familiar with the hybrid electric vehicle (HEV). Another form of a hybrid is the plug-in hybrid electric vehicle (PHEV). It functions the same way as an HEV does, by using batteries to smooth a vehicle’s power requirements and optimize the efficiency of the gasoline engine, except where an HEV’s batteries recharge using regenerative braking, the PHEV’s batteries regenerate using an external power source, such as a standard wall outlet. In this way, the PHEV may operate as a purely electric vehicle and only use the gasoline engine on extended trips. Manitoba Hydro studied a modified Toyota Prius to estimate the potential power requirements on the province’s electrical distribution system should PHEV’s become more popular in this province.

The second half of the evening was a tour of the Manitoba Electric Museum, which portrays the history of electrical distribution in Manitoba from the 1870s to the present, as well as a view into the future. The museum holds many artefacts of electrical equipment used over the years, both in households and in power distribution and is housed in an artefact itself. The building itself was built in 1931 and was then known as the Fort Garry Station. Within the lobby, a visitor has a view of the electric panels used for switching and monitoring electricity in that past. The main gallery of the museum houses an actual streetcar from Winnipeg’s past and showcases some of the many style of light bulbs used over the years.

Manitoba is fortunate in that much of the province’s landscape is terrain ideal for electrical power generation using hydro dams. The museum highlights the history of power generating systems in the province. Farm electrification was a large scale project of Manitoba Hydro to add electricity to the rural areas of the province. In the past 30 years, the focus moved north to larger scale generating stations that will continue to serve the province into the future. Lastly the museum covers potential power sources for the future, such as wind. The museum is located at 680 Harrow Street.

The 2009 Corvette ZR1, with speaker Jerry Burton

September 6, 2008

written by Bob Mai

It was with great honour that SAE Manitoba Section, the Corvette Club of Manitoba, and the city of Winnipeg hosted Jerry Burton, editor for Corvette Quarterly, this September weekend. Jerry flew in from Michigan, stayed at the Fort Garry Hotel, enjoyed some Rae and Jerry's, some WSCC autocrossing, a Corvette Club car show, and, of course, spoke about the 2009 Corvette ZR1 in a hall of around 105 paid attendees.

The presentation was held at the Headingley Community Centre, where the Automobile Museum was opened up to the paying public. Around 40 Corvettes and 12 non-Corvettes participated in the car show preceding the presentation. After the dinner and presentation, awards were presented to car show winners, and Jerry took orders for personalized books. All in all, it was a successful event for all involved, and SAE Manitoba delivered a $500 cheque to the Rainbow Society!